服务热线:4000 678 165

SANITATION 消毒

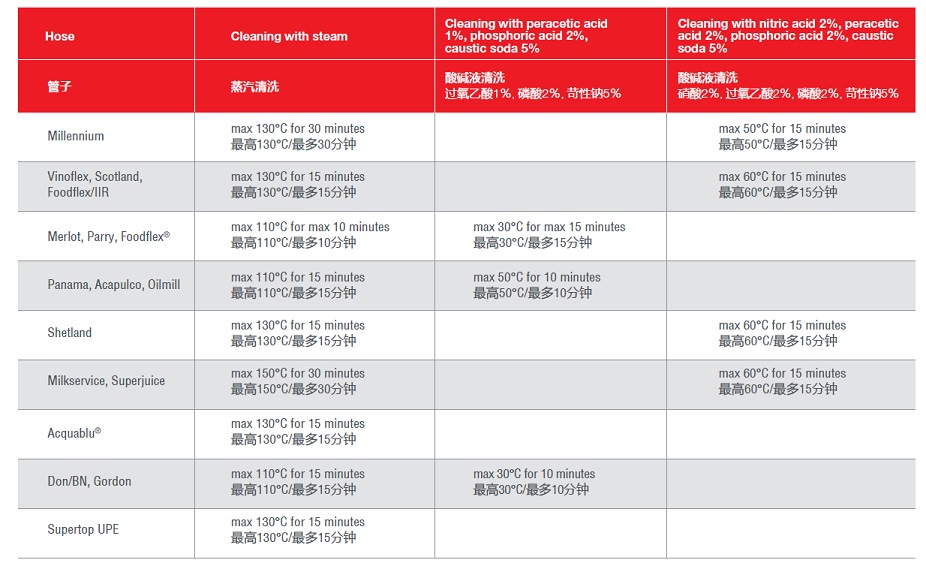

1.On first use IVG recommends a wash cycle with potable water at a maximum

temperature of 80°C/90°C and a hose sanitation before conveying food products.

首次使用,在输送食品前,IVG 建议用不超过80℃/90℃温度的饮用水循环

清洗和消毒管子。

2.Detersion and disinfection of systems and hoses should be checked at the end

of each cycle of use.

应该在使用的每个周期结束时 进行检查, 清洗以及系统消毒。

-Strictly follow the times indicated for each cleaning cycle.

-严格遵循对每道清洗周期所规示的时间。

-Do not immerse hose assembly in the sanitation fluid because only the tube is suitable for getting in touch with the above mentioned solvents.

-不要沉浸胶管总成在消毒液里,因为仅内管适合接触上面提到的溶剂。

-Every cleaning cycle must be immediately followed by a complete rinse.

-每个清洗周期后必须做一个完整的冲洗。

-Hoses are not suitable for permanent stagnation of products.

-软管不适合产品永久滞留在内。

-Keep hoses away from sunlight and heat, and store with pierced plugs on both ends.

-保持软管远离阳光和热量,并在两端装防尘塞储存。

Below are the notes for the proper use of the product in ATEX environments and warnings resulting from the risk analysis for the verification of effective ignition sources.

以下是在防爆环境下正确使用该产品的提示以及来自于有效火源的核查的风险评估的警告。

Note A – Hot surfaces

提示A - 热表面。

The hose does not contain heat sources so the surface temperature of the hose depends strictly on the use by the end user. In the pneumatic conveying systems periodically check the integrity of the hose and its layers.

Do not use the hose if the inner layer is heavily worn. The range of the working temperature of the material for which we guarantee the properties is according to the technical data sheet of the product.

Damage resulting from improper use of the product are not attributable to the manufacturer.

管子不含热源,所以管子表面温度完全由用户的使用决定。在气动传送系统内定期检查软管和它的各层的完整性。

如果管子内层严重磨损,请不要使用。我们保证的材料的工作温度范围请依据产品的技术参数表。

因不当使用产品而导致的损坏厂商概不负责。

Note B – Sparks of mechanical origin

提示B - 机器原始火花

The hose has no moving parts and it is not able to generate this source of ignition. In the pneumatic conveying systems it is likely that sparks are carried from earlier process operations and not due to the hose itself. It is the end user’ s responsibility to operate so that this source of ignition is not present, internally and externally to the hose.

该软管没有运动部件,这是不能够产生火源的。

在气动传送系统内很可能从早期的处理操作产生火花,而不是由软管本身产生。用户有责任确保在操作中不要给管子的内部和外部带来火花。

Note C – Electrical equipment

提示C - 电气设备

There is no electrical materials provided with the hose. The possible steel helix wire (if present between the layers of the hose) has been designed, to impart mechanical strength to the hose. The helix wire is not intended as an electrical conductor but it can help the dispersion of electrostatic charges if and only if it is correctly connected to the ground line or to equipotential bonding jumpers with equipment already connected to the ground line.

软管无生电材料。可能的钢螺旋线(如果该软管的各层之间存在的话)已经被设计传递机械力到管子上。螺旋丝不可作为电导体,但当且仅当它被正确地连接到接地线或设备已经连接到接地线的等电位连接跳线的时候,它可以帮助静电电荷的分散。

Note D – Eddy currents

提示D - 涡流

This ignition source is not applicable to the hose in question. The end user must operate so that the hose is not isolated from sections of insulating hoses. The hose, thanks to its conductive/dissipative characteristics is able to disperse possible electric/electrostatic charges accumulated during the process if and only if the hose is properly connected to the ground line.

此着火源并不适用于所讨论的软管。用户在操作中必须确保软管不会从绝缘软管的部分分离出来。由于其导电性/耗散的特点,当且仅当软管被正确地连接到接地线时,软管是有可能分散在过程中积累的静电荷。

Note E – Electrostatic charges

提示E - 静电

The hose does not contain or inherently generates electrostatic ignition sources. Eventual generation and accumulation of charges may depend on the material transported in the process and the ability of the material, properly connected with equipotential connections and/or connections with grounding, to be able to drain them. Care should be taken in the perfect cleaning and maintenance of connections

and periodic assessment of the earth resistance that can detect anomalies in the system. The material the hose is made of has been designed to maximize the dispersion of electrostatic charges that can be generated due to the process. The nonapplication of these notes and improper use of the product as designed, absolve the manufacturer from any responsibility for any damage that may

result. According to the characteristics and needs of the process that may generate internal and external hazardous atmospheres, detailed studies should be performed by experienced staff to guarantee a proper use of the product.

The concepts, recommendations, references and the limits reported in the following standards are extremely important in order to carry out a detailed study:

• CEI 3155 – CLC / TR 50404 – Electrostatics – Code of practice for the avoidance of hazards due to static electricity

• NFPA 77 - 2014 - Recommended Practice on Static Electricity

• UNI EN 13463-1-2009 – Non-electrical equipment for use in potentially explosive atmospheres-Basic method and requirements

• UNI EN 1127-1/2007 Explosive atmospheres. Explosion prevention and protection – Part 1: Basic concepts and methodology

软管不包含或本身不产生静电火源。最终产生和累积电荷取决于在此过程中输送的材料和该材料的性能,正确连接在具有接地连接的等电位连接跳线上,以便能够排出它们。注意,必须做彻底的清洁和连接维护及接地电阻的定期评估,来检测系统中的异常。

软管制成的材料已被设计为最大化分散使用过程中产生的静电电荷。不正确应用这些提示和不当使用所设计的产品,制造商不对可能引起的任何损失承担任何责任。根据产品的特点和可能产生的内部和外部危险环境的过程中需要,详细研究应由有经验的工作人员来进行,以保证产品的正常使用。

为了进行详细的研究,概念,建议,参考文献和公开在下面的标准范围是非常重要的:

• CEI 3155 – CLC / TR 50404 - 静电学 -避免静电危险的工作守则

• NFPA 77 - 2014 - 关于静电的推荐规则

• UNI EN 13463-1-2009 - 使用的非电气设备的潜在爆炸性环境的基本方法和要求

• UNI EN 1127-1/ 2007爆炸性环境。防爆和防护 - 第1部分:基本概念和方法

Note F – Adiabatic compression and shockwaves

提示F - 绝热压缩和冲击波

It is not applicable to the supplied hose. The possible releases of gas at high speed can only be caused by the process. The user must assess the possible presence of this ignition source before putting the hose into use.

它并不适用于所提供的软管。气体高速释放的可能性,只可能由工艺引起的。软管开始使用前,用户必须评估火源的可能存在。

Note G - Temperature increases due to chemical reactions or unstable materials

提示G - 由化学反应或不稳定的材料引起的温度升高

Chemical incompatibility of the materials of the hose with the product/s to be conveyed. Verify in the design phase and before use, the chemical compatibility of the substances used in the process with the material of the hose. For any questions or doubts, please contact IVG Colbachini for the necessary compatibility checks.

软管的材料与要输送的产品具化学不相容性。在设计阶段和在使用前,检查所述软管的材料和输送物质的化学相容性。如有任何疑问或质疑,请联系IVG进行必要的兼容性检查。

Note H - Combustion of a layer of powder or other combustible material: presence of dust between moving parts

提示H - 一层粉末或其他可燃物质的燃烧性:运动部件之间的存在粉尘

The ignition source is not inherently present in the product supplied. Correct transport speeds could prevent accumulations of the dust.

Periodic cleaning prevents dust accumulations that, besides modifying and make less effective the dissipative characteristics of the material,could promote this kind of ignition.

点火源不是固有存在于所提供的产品。正确的传输速度可以防止灰尘堆积。除了改进和降低耗散材料的特性,定期清洗可防止灰尘积聚而产生火源。

For special needs please contact us directly.

有问题和特殊要求请直接联系我们。